Industrial robots gain multitasking capabilities for efficiency

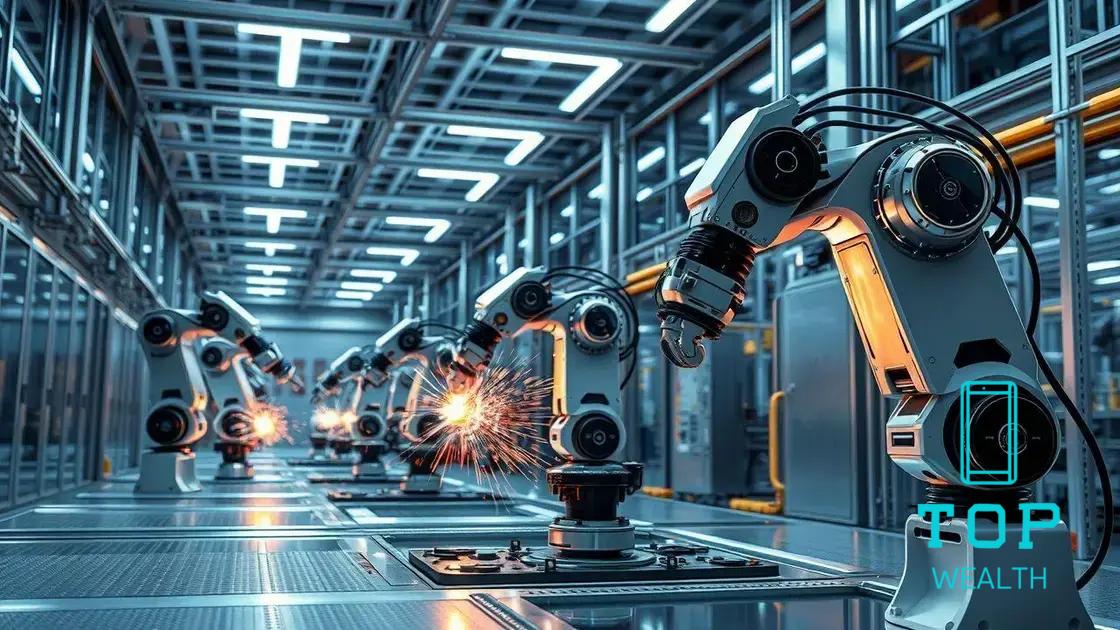

Industrial robots gain multitasking capabilities, allowing them to perform multiple operations simultaneously, which enhances productivity, reduces costs, and improves efficiency across various industries like manufacturing, logistics, and healthcare.

Industrial robots gain multitasking capabilities, allowing manufacturers to streamline operations and boost productivity. Have you considered how these advancements could transform your industry?

Understanding multitasking in industrial robots

Understanding how multitasking in industrial robots works is vital for any business looking to boost productivity. These robots can perform several tasks at once, significantly improving efficiency on the production line. This capability not only saves time but also leads to reduction in labor costs.

What is Multitasking?

Multitasking refers to a robot’s ability to handle multiple operations without needing to stop. This is accomplished by using advanced software and sensors, which allow robots to program their tasks effectively. Here are some critical features:

- Parallel task execution: Robots can manage several tasks simultaneously, leading to smoother workflows.

- Adaptive programming: Unlike traditional robots, multitasking robots can adapt on the fly, responding to new tasks as they arise.

- Sensor integration: With integrated sensors, robots can recognize their environment and adjust their tasks accordingly.

The core advantage of these systems is flexibility. Imagine a robot assembling a part, inspecting it, and then packaging it all in one continuous operation. As industries strive for greater efficiency, this technology is becoming critical.

Benefits of Multitasking Robots

Implementing multitasking robots can transform an entire production line. Some significant benefits include:

- Cost savings: Reduced need for multiple machines lowers overhead expenses.

- Time efficiency: Completing tasks in a single step saves valuable time in production.

- Quality improvement: Fewer human hands on processes reduce the risk of errors.

This adds up to a game-changing approach for manufacturers. As companies adapt, they can ensure they stay competitive and meet the ever-increasing demands while maintaining quality.

Understanding multitasking in industrial robots is just the start. The technology continues to evolve, making it essential for businesses to stay informed.

Benefits of multitasking capabilities

Understanding the benefits of multitasking capabilities in industrial robots can significantly enhance productivity and operational efficiency. These robots are designed to perform several tasks simultaneously, allowing businesses to streamline their processes and reduce downtime.

Increased Efficiency

One of the most notable advantages is the increased efficiency these robots bring to manufacturing processes. By executing multiple tasks at once, they minimize the time spent on each project. Some key points include:

- Faster production times: Robots can operate without breaks, leading to quicker turnaround for products.

- Reduction in idle time: Multitasking reduces the need for machines to wait for human intervention.

- Enhancement of output quality: Continuous operation leads to consistency in production quality.

This integration allows for better resource management. For instance, one robot can be responsible for assembly, while another handles inspection, all without the need for separate setups.

Cost Savings

Another major benefit is the significant cost savings associated with multitasking robots. Companies can expect to see:

- Reduced labor costs: Fewer workers are needed when robots handle multiple tasks.

- Lower equipment expenses: One multifunctional robot covers the roles of several single-task machines.

- Minimized maintenance costs: Fewer machines can result in lower maintenance and repair costs.

These factors contribute to a better return on investment over time. Companies that utilize multitasking capabilities often find themselves more competitive in the market due to these savings.

As industries evolve, the integration of multitasking productivity becomes crucial. Businesses that invest in this technology stand to gain not just in immediate efficiency, but also in long-term sustainability and profitability.

Key technologies enabling multitasking

Several key technologies enabling multitasking in industrial robots play a crucial role in enhancing their effectiveness. These advancements allow robots to operate on multiple tasks, which is essential in today’s fast-paced manufacturing environment.

Advanced Sensors

One of the primary technologies is the use of advanced sensors. These sensors collect data about the robot’s environment, providing real-time feedback. Some features include:

- Proximity detection: Sensors can identify nearby objects, allowing robots to navigate safely.

- Vision systems: Cameras and imaging technology help robots recognize products and make decisions based on visual input.

- Force sensing: This technology enables robots to apply the right amount of pressure, crucial for handling delicate components.

With these sensors, robots can adapt their actions based on what they encounter, increasing their ability to multitask.

Artificial Intelligence

Another significant technology is artificial intelligence (AI). AI algorithms allow robots to learn from past experiences, optimizing their performance over time. This learning capability helps them operate more autonomously and efficiently.

Furthermore, AI facilitates complex decision-making processes. For example, it enables robots to prioritize tasks based on production needs, switching from one job to another seamlessly. This flexibility is vital for maintaining high productivity in a dynamic workspace.

The integration of these technologies into multitasking robots leads to sophisticated systems that can significantly improve workflow. As businesses implement these robots, they often experience enhanced efficiency and productivity.

Overall, the combination of advanced sensors and artificial intelligence equips industrial robots with the tools they need to excel at multitasking, setting new standards in manufacturing.

Real-world applications of multitasking robots

Real-world applications of multitasking robots showcase the incredible capabilities these machines bring to various industries. By combining multiple tasks into one streamlined operation, businesses can greatly increase efficiency and productivity.

Manufacturing

In manufacturing, multitasking robots can handle assembly, inspection, and packaging simultaneously. This approach reduces production time while ensuring high-quality output. For example:

- Automotive industry: Robots can assemble parts, conduct quality checks, and package components in one seamless workflow.

- Electronics: Robots assemble delicate electronic devices, performing tasks like soldering and quality control simultaneously.

- Food and beverage: Multitasking robots efficiently manage packing, sorting, and labeling products on production lines.

These examples highlight how multitasking robots help decrease operational costs while improving speed and accuracy.

Logistics

In logistics, multitasking robots also play a vital role. They assist in warehouse operations by managing inventory, picking and packing items, and even loading trucks. This leads to faster turnaround times and enhanced accuracy in order fulfillment:

- Automated sorting: Robots can effortlessly sort packages based on size and destination.

- Real-time tracking: Using advanced sensors, they can monitor inventory levels and notify managers about stock needs.

- Delivery: Robots are increasingly used for last-mile deliveries, offering efficient and timely service.

These applications demonstrate how multitasking robots help companies meet growing consumer demands while maintaining operational efficiency.

In healthcare, multitasking robots facilitate surgical procedures and pharmacy automation, promoting better patient care and reducing human error. Their adaptability makes them valuable assets across various service sectors as well.

Ultimately, as industries continue to evolve, the use of multitasking robots will become even more prevalent, leading to advancements that can reshape entire business models.

Future trends in robotic multitasking

The future of robotic multitasking is shaping up to be exciting and transformative. As technology advances, we can expect to see significant changes that enhance how robots operate across various industries.

Integration of AI and Machine Learning

One of the most impactful trends is the integration of artificial intelligence (AI) and machine learning into multitasking robots. This integration allows robots to learn from their environments and improve their performance over time. Notable aspects include:

- Adaptive algorithms: Robots will be able to adjust their actions based on real-time data, making them more responsive to changing conditions.

- Predictive maintenance: AI will enable robots to anticipate issues before they occur, reducing downtime.

- Enhanced learning: With machine learning, robots can develop skills from their experiences, leading to more efficient multitasking.

This progress will significantly enhance the flexibility and capability of robots in the workplace.

Collaboration with Humans

Another trend is the rise of collaborative robots, or cobots, which work alongside humans. These robots will become more intuitive and safe, allowing for smoother interactions. Key features include:

- Safety enhanced: Advanced sensors will ensure that robots can work safely near human operators.

- Shared tasks: Cobots can take over repetitive tasks while humans focus on more complex operations.

- Easy programming: New interfaces will allow employees to program robots with minimal technical know-how.

The collaboration between robots and humans can lead to improved workflows and more balanced production environments.

In addition, as sustainability becomes a priority, future robots are expected to be designed with energy efficiency in mind. This might include the use of renewable energy sources and materials that reduce environmental impact.

The advancements in technology will also allow these robots to operate in more complex environments, such as homes and public spaces, further broadening their application.

Overall, the future trends in robotic multitasking are oriented towards making robots smarter, safer, and more adaptable, setting the stage for a new era in automation.

In summary, the advancements in robotic multitasking are revolutionizing various industries. With the integration of AI and machine learning, robots will become more adaptive and efficient. Collaborating robots, or cobots, will improve safety and productivity in workplaces by working alongside humans. As sustainability becomes a priority, new robots will also focus on being energy-efficient. The ongoing innovations promise a future where robotic multitasking plays a crucial role in enhancing productivity and transforming how we work.

FAQ – Frequently Asked Questions about Robotic Multitasking

What are the main benefits of robotic multitasking?

Robotic multitasking improves efficiency, reduces costs, and enhances productivity by allowing robots to perform multiple tasks simultaneously.

How does AI enhance robotic multitasking capabilities?

AI enables robots to learn from their environments and experiences, allowing them to adapt their tasks and improve their performance over time.

What industries are most impacted by multitasking robots?

Manufacturing, logistics, and healthcare are among the industries that benefit significantly from the use of multitasking robots.

What is the role of collaborative robots (cobots)?

Collaborative robots work safely alongside humans, handling repetitive tasks and allowing human workers to focus on more complex activities.